Custom Membrane Switches FAQ

Release time:2023-10-21 Click:240

What are custom membrane switches?

Custom membrane switches are user interface devices that consist of a flexible, thin, and durable membrane overlay mounted onto a rigid or flexible circuitry layer. They are used to provide a user-friendly interface for electronic devices and equipment.

How do custom membrane switches work?

Custom membrane switches work by using a conductive layer sandwiched between two layers of a non-conductive material. When a user presses on a specific area of the membrane switch, it activates the conductive layer, causing electrical circuits to close and trigger the desired response or function.

What are the advantages of using custom membrane switches?

A: Custom membrane switches offer several advantages. They are compact, lightweight, and provide a low-profile design that is ideal for space-constrained applications. They are also cost-effective to manufacture, customizable, and can be tailored to fit specific design requirements. Additionally, membrane switches are highly resistant to dirt, moisture, and chemicals, making them suitable for a wide range of environments.

What applications are custom membrane switches commonly used in?

Custom membrane switches are commonly used in various industries and applications. They can be found in medical devices, industrial control panels, consumer electronics, automotive dashboards, home appliances, aerospace equipment, and many other electronic devices and equipment.

What customization options are available for custom membrane switches?

Custom membrane switches can be customized in terms of size, shape, color, graphics, and tactile feedback. They can incorporate different types of switches, such as tactile, non-tactile, or domed switches, to provide the desired tactile response for the user. Additionally, backlighting options and integrated LED indicators can be added for enhanced visibility.

How long do custom membrane switches last?

The lifespan of custom membrane switches depends on factors such as usage frequency, environmental conditions, and quality of materials used. However, with proper use and maintenance, membrane switches can typically last for thousands of actuations.

Can custom membrane switches be waterproof?

Yes, custom membrane switches can be designed to be waterproof or resistant to moisture and environmental contaminants. Special materials and sealing techniques can be utilized to ensure the membrane switch remains operational even in wet or harsh environments. Waterproofing ratings and requirements should be discussed with the manufacturer during the customization process.

How are custom membrane switches manufactured?

Custom membrane switches are manufactured using a combination of printing, die-cutting, and assembly processes. The layers of the membrane switch are precision printed with conductive inks, graphics, and adhesives. The layers are then die-cut into the desired shape and assembled using advanced techniques to create a functional membrane switch.

Membrane Switch FAQ

Why do I need a membrane switch supplier?

If you are a manufacturer or product designer, you might need a membrane switch supplier to source and provide you with high-quality and customized membrane switches for your specific applications. They specialize in the design, manufacture, and supply of membrane switches in varying shapes, sizes, and functionalities.

What services do membrane switch suppliers offer?

Membrane switch suppliers typically offer a range of services, including design assistance, prototyping, manufacturing, quality control, and product customization. They can work closely with you to understand your specific requirements and deliver tailor-made solutions.

How do I choose the right membrane switch supplier?

When selecting a membrane switch supplier, it’s important to consider factors such as their experience, industry reputation, manufacturing capabilities, design expertise, product quality, and customer support. Requesting samples or discussing your project requirements with potential suppliers can help you make an informed decision.

Can membrane switch suppliers handle large-scale production orders?

Yes, reputable membrane switch suppliers have the infrastructure and capacity to handle both small-scale prototyping and large-scale production orders. They use advanced manufacturing techniques and automated processes to ensure consistent quality and quick turnaround times.

What industries use membrane switches?

Membrane switches are widely used in various industries, including medical equipment, industrial control systems, consumer electronics, automotive applications, telecommunications, aerospace, and more. They provide a reliable and cost-effective interface solution in these sectors.

Can membrane switches be customized?

Yes, membrane switches are highly customizable. Membrane switch suppliers can work with you to incorporate specific features like custom graphics, tactile feedback, backlighting, embossing, and integration with other components to meet your unique design requirements.

Membrane Switch Assembly FAQ

Sure! Here are some frequently asked questions about membrane switch assembly:

What is a membrane switch assembly?

A membrane switch assembly is a user interface that combines a thin, flexible membrane switch with other components such as graphic overlays, circuitry, and backlights. It is commonly used in various electronic devices and appliances as a convenient and reliable input interface.

How does a membrane switch work?

A membrane switch works by using pressure-sensitive conductive materials, normally polyester or polycarbonate layers, to create a circuit. When the user applies pressure to a specific area of the switch, it closes the circuit and sends a signal to the device. Membrane switches are designed to be flat and easy to clean, making them suitable for many applications.

What are the advantages of using membrane switch assemblies?

Membrane switch assemblies offer several advantages, including:

Compact and low-profile design

Resistance to moisture, dust, and other contaminants

Durability for millions of actuation

Customizable graphics and backlighting options

Cost-effective compared to other switch technologies

Easy integration into devices and appliances

Can membrane switch assemblies be customized?

Yes, membrane switch assemblies can be fully customized to meet specific design requirements. The graphic overlays can be printed with custom designs, logos, icons, and color schemes. Additionally, the switch layout, dimensions, and features can be tailored to fit the application.

What industries use membrane switch assemblies?

Membrane switch assemblies are utilized in various industries, including medical devices, aerospace, automotive, industrial equipment, consumer electronics, and appliances. They are found in equipment such as control panels, keypads, touchpads, and instrumentation interfaces.

Can membrane switch assemblies be backlit?

Yes, membrane switch assemblies can incorporate backlighting features. The switches can be designed with embedded LEDs or light guides to provide uniform lighting for better visibility, especially in low-light or dark environments.

Hot products

-

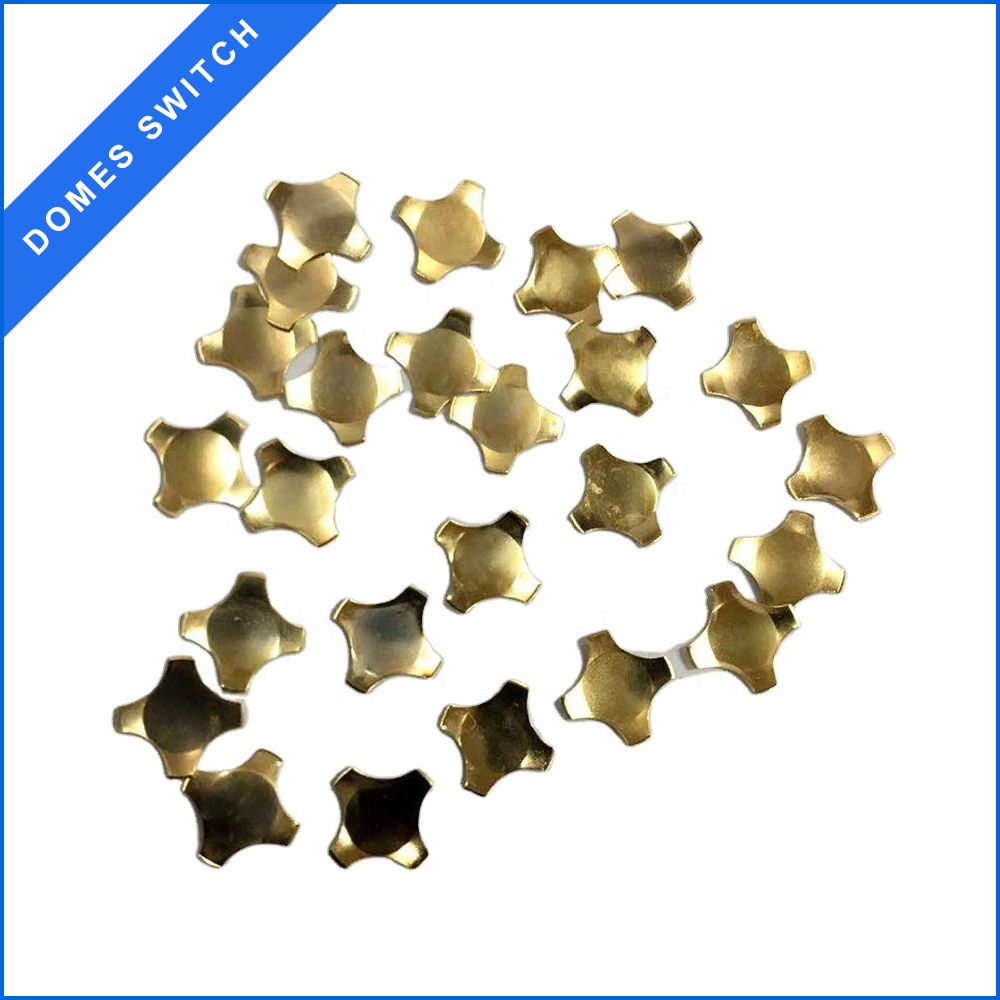

16MM Four Leg Metal Domes

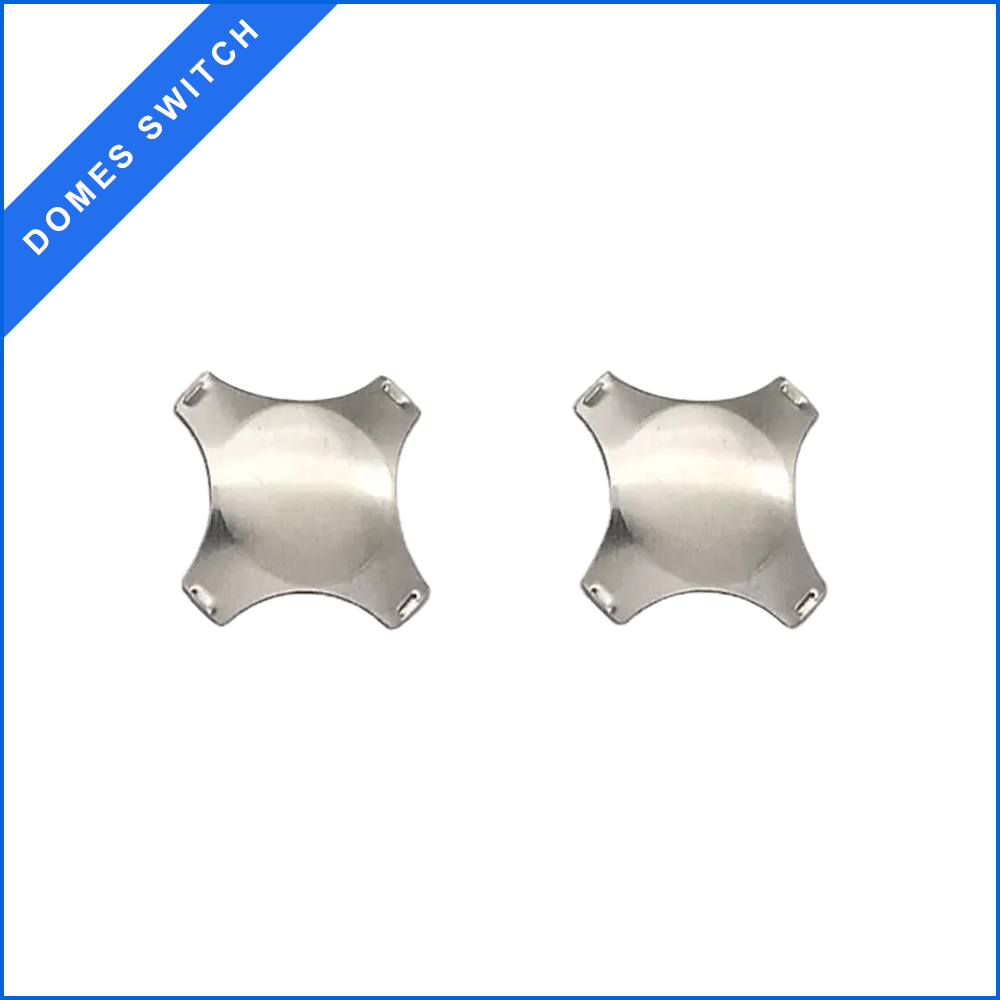

-

Stainless Steel Metal Dome

-

Custom 30-50mm metal dome factory

-

6mm Four-leg Metal dome factory

Tel:13544111814

E-mail:admin@ruxian8.com